Unlearning habits is hard. I spent a lot of time learning how to use power tools to fix up our old house. But as "home improvement" gave way to greater ambitions, I found I was drawn more and more to hand tool woodworking. This led to an interest in work holding for hand tool operations, which led to Chris Schwarz's workbench book.

As often happens when you're part of a family raising young children, I did more dreaming than doing. Some of that is my own fault, for not seizing opportunities. Some of that is just the definition of raising a family.

Recently, I finished my Roubo-style workbench as described by Chris, and with vises by Benchcrafted. And now the transformation has begun.

I decided to build a kindling holder. We have a high efficiency wood insert in our fireplace and it's become tedious to remember the bits of kindling to get the fire started properly. A friend recently gifted me with some pine removed while redoing a room in their house. So I decided to throw together a simple rectangular box to hold kindling by the fireplace.

After practicing some hand tool flattening (the boards would end up about 10 inches wide and it seemed a shame to rip them down to fit my 6" jointer), I nailed and glued up the main carcass. When I went to make the bottom, I wanted it rabbeted to provide a cleaner look and stronger joint. But my glue-up was not quite perfect and the box, which looked completely square, was off a bit.

I could have trashed the piece and started over. But it looks square (it's off by less than a degree) and the wood is beautiful. And it's a kindling holder for pity's sake.

That's when I realized my new workbench offered an answer. With the wagon vise, a holdfast, a clamp, and scrap piece, I had a perfect jig for a backsaw to saw the edges of the rabbet. It took literally a minute to set up, including planing the edge of the guide scrap flat.

Once the edges were sawn, a router plane and shoulder plane finished the work quickly and with no dust or noise.

In less than fifteen minutes from idea to finish, I'd rabbeted all the edges of the bottom and router-planed them to fit. Trying to find a solution with power tools would have taken me at least an hour, a lot of noise and dust, and a nervous moment or two.

Chris Schwarz was incredibly kind during my bench build. I suspect he's so tired of workbench questions he would like to just scream when he gets another email about it. When I had almost finished my bench and sent him proud pictures, he nonetheless responded kindly, complimenting my bench and stating he thought it would transform my work.

I am happy to report he was right. Tonight was just the latest in a series of wonderful moments when I needed to hold my work and found a quick and reliable way with this workbench.

An exploration of my efforts to become worthy of the titles "furniture maker" and "cabinetmaker".

Monday, December 29, 2014

Saturday, December 20, 2014

Sunday, October 5, 2014

Almost there

Almost ready to join the base and the top of my workbench.

Now is the time to be patient. Rushing will ruin many, many hours of work.

Tuesday, August 5, 2014

The Measure of a Life

I've said it before, but the passing of someone I wish I'd known prompts me to say it again.

The measure of a life is not so much about the things we 'accomplish', as it is the company we keep.

-- Brian

The measure of a life is not so much about the things we 'accomplish', as it is the company we keep.

-- Brian

Saturday, April 19, 2014

Better Late Than Never

I'm not going to say how long these savings boxes have been in the works. Happily, they are finally done.

Tuesday, December 4, 2012

It's not dead yet...

Not like anyone is waiting with baited breath, but I hope to resume writing about woodworking soon. Ebb, and flow, ebb and flow...

[Obligatory Monty Python reference...]

[Obligatory Monty Python reference...]

Wednesday, September 8, 2010

Shoot the Moon

I've been working on a small display cabinet (a sort of shadow box almost) for my mother-in-law, Penny, for much too long. Unlike the conventional wisdom about mother's-in-law, Penny is a wonderful person, and she has demonstrated it yet again by her patience and good nature. Not once did she ask about progress on her cabinet in the too many months it has taken me to build it. I could bore you with an explanation of the many events going on in my family's life that have contributed to my slowness. And I could whine about how my inexperience at matching finishes cost me several weeks of trial and error in matching the stain on my cabinet to the other cabinetwork it will be installed amongst. But I won't.

So this last weekend (Labor Day weekend here in the States), I was faced with the final task. I had made custom moldings to go on the front of cabinet, much like a picture frame. But I needed to miter the corners and install the moldings. I've cut miters before, always with my power miter saw. And in all honesty it's an exercise in fear and frustration. With a miter saw blade spinning at something like 3,600 RPMs, there is a serious element of fear, even with proper wedging and clamping. And frustration is on the high side as well. I'm sure if I cut as many miters as professionals do, I would soon find it much more natural. But it's always a challenge to get that miter just the way it needs to be, especially if you are matching one you cut that is not quite 45 degrees.

So, I took the plunge and made a shooting board. I've read many articles about shooting boards, and they appeal greatly to my continued foray into hand woodworking. I was encouraged by the description of the precision you can achieve with them. I wanted to reward all of Penny's help and patience (over the last year especially) with the very best I could build. So, after one more look over the articles, I settled on a design for a shooting board that would work for both right angles and miters.

Rather than write up a long description of shooting board design, I'll refer you to several resources I found very helpful:

So this last weekend (Labor Day weekend here in the States), I was faced with the final task. I had made custom moldings to go on the front of cabinet, much like a picture frame. But I needed to miter the corners and install the moldings. I've cut miters before, always with my power miter saw. And in all honesty it's an exercise in fear and frustration. With a miter saw blade spinning at something like 3,600 RPMs, there is a serious element of fear, even with proper wedging and clamping. And frustration is on the high side as well. I'm sure if I cut as many miters as professionals do, I would soon find it much more natural. But it's always a challenge to get that miter just the way it needs to be, especially if you are matching one you cut that is not quite 45 degrees.

So, I took the plunge and made a shooting board. I've read many articles about shooting boards, and they appeal greatly to my continued foray into hand woodworking. I was encouraged by the description of the precision you can achieve with them. I wanted to reward all of Penny's help and patience (over the last year especially) with the very best I could build. So, after one more look over the articles, I settled on a design for a shooting board that would work for both right angles and miters.

Rather than write up a long description of shooting board design, I'll refer you to several resources I found very helpful:

- Finewoodworking.com - if you have a subscription, there quite a few articles and 'tips' regarding shooting boards. If you instead have a old issues of Fine Woodworking, the May/June 1994 magazine has a short article that inspired my removable 45 degree stop.

- There is a really good article on the Popular Woodworking website.

- "The Handplane Book" - by Garrett Hack, a wonderful text on all things hand plane

- "Shooting Boards @ Cornish Workshop" - this is perhaps the most important link. Not only is it informative and filled with links to other online references, but Alf's no-nonsense write-up convinced me that "It's Not Rocket Science" and it was worth a brief 'diversion' to achieve better results for Penny's cabinet.

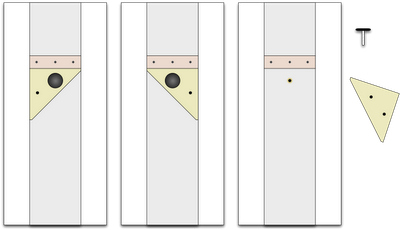

So I settled on a design, a blending of several different ones I've seen over the last few years. I chose to make a single board that has a shelf on both sides. While this means aligning the stop block at exactly 90 degrees is particularly important, it means only one shooting board in my shop for mitering on either the left or the right. And with a removable 45 degree block, I can orient for 45 degree miters on either side in less than a minute.

One of the surprising things I learned from Alf's shooting board pages was that most of the dimensions of a shooting board aren't all that important. The only key dimension is the size of the shelf on which your hand plane rests. It needs to be wide enough that you can apply good, firm pressure down and toward the cut without having your hand plane tip over.

I decided to go with the removable 45 miter block in order to build only one shooting board (at least until I want to do "dog-ear" miters). That proved to be tremendously helpful when it came time to fit my trim on Penny's cabinet. My angles weren't quite 45 degrees and I simply added a piece of paper or card stock to one end or the other of my angle block to finesse the angle into what I needed. Because I have a threaded insert and a knob with threaded rod to lock the miter block in place, I can adjust the wedge to where I need it and to as many cuts and test fittings as needed to get a good fit without worrying that my shooting board setup will change.

Since I was going to use a shooting board, I decided it was time to try out the hand miter saw I got several months ago. It's not in perfect shape. It has some rust that needs removing on the box and saw guide, and the paint is flaking and needs to be scraped and repainted. Plus the saw itself (a nice large example with a 26" length) was rusty enough that I left rust marks on the scraps I used for test cuts. So I took some time to clean the blade, clean the gunk from the corners where the bed and fence meet, and experimented until I was comfortable that my cuts were close enough to 45 degrees for good results.

I still need to finish cleaning up the miter box but now that I've used it with success, that time will be much more pleasurable to spend.

Once I had completed the shooting board, it was time to actually cut the last two pieces of molding and make them fit the two I had already glued to the cabinet carcass. I will admit I "took a break" and went upstairs for a bit. After a suitable length of "rest" (also known as gathering my nerve), I went back down and set to work.

The first piece I cut was definitely too long by more than an 1/8th of an inch. But that turned out to be a good thing. While I had experimented with some scrap pieces, that's just not the same as taking custom made molding to a shooting board you've never used before. That extra length gave me time to learn the feel of my shooting board, and I learned a lot about reading the angles and the fit. I also realized immediately how much more I was enjoying the process with hand miter box and shooting board versus power miter saw. The finesse the shooting board gave me, the soft "shhnick" from taking a truly fine shaving by hand, the quiet of the workshop, and not having to pay huge attention to a saw blade spinning at 3,600 rpm made the process a joy instead of a test of will with a dash of fear.

So now Penny's display cabinet is finished, and I have a shooting board I will use to improve my results for years to come.

Once I get Penny's case installed, of course...

Subscribe to:

Posts (Atom)